PAHWA METALTECH P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PAHWA METALTECH P LTD.

Non Sparking Hand Tools

Non-sparking tools is mandatory to provide protection against fires and explosions in environments where there is a possibility of sparks igniting flammable solvents, vapours, liquids, dusts or residues.

Conventionally Non-Sparking Hand Tools were available of the following two materials i.e Copper Beryllium and Aluminium Bronze.

Copper Beryllium (Cu-Be) is an extremely hazardous alloy due to the toxicity associated with Beryllium. Use of Cu-Be hand tools or other parts, constantly exposes employees and contractors to a severe and often fatal lung disease caused by exposure to Beryllium. You read more about hazards of beryllium on our technology page.

Resistance Welding Products

Copper Alloys find its very common application in resistance welding equipment and tools.

Selecting the right copper alloy for resistance welding equipment particularly for gun arms, Projection welding electrodes, Seam welding wheels and Spot welding electrodes and caps is dependent on large number of design criteria and most often it is a trade-off between strength and electrical conductivity.

Copper Chromium and Copper Chromium Zirconium alloys have good thermal conductivity but tend to soften at lower temperatures thereby by significantly reducing the quality of weld and life of electrode. Copper Beryllium (RWMA Class 3 and 4) alloys are used high weld force or high weld currents are required. However these alloys are expensive for commercial applications and therefore are ususally substituted with less expensive materials.

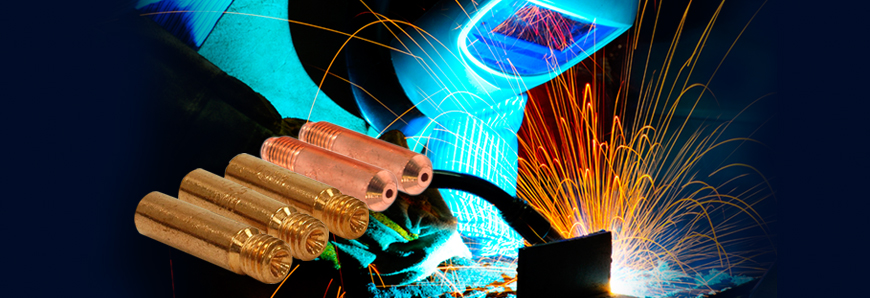

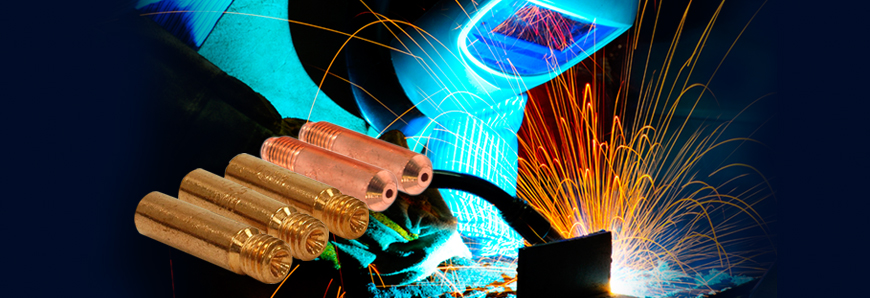

Mig Welding Contact Tips

Softer/Lower strength copper alloys contact tips tend to wear out quickly leading to downtime and reduced productivity. Worn tips are typically become oval and can cause an erratic arc from the random electrical connection and physical movement of the wire inside the worn tip.

Contact tips precisely made from a wear-resistant copper alloy can give superior welding performance. Copper Beryllium tips have high wear resistance but are expensive to use.

Plunger Tips

Plunger Tips is a critical part of aluminium Die-casting process. Plunger tips are used to push molten zinc and aluminium through a polished steel sleeve into die cavities, to form intricate parts. Beryllium Copper Plunger Tips have been the standard of the Die Casting Industry for the past 30 years. Beryllium Copper Plunger Tips generally do not last much longer than 9,000 shots under the best conditions and with a relatively small diameter. Above all Copper Beryllium material itself is highly expensive and pose health concerns. CI and tool steels plungers have been used to overcome the disadvantages of cost of CuBe Plungers but lack performance. Steel Plungers are relatively inexpensive but wear out more frequently and have to be replaced regularly, thereby increasing downtime and poor productivity.

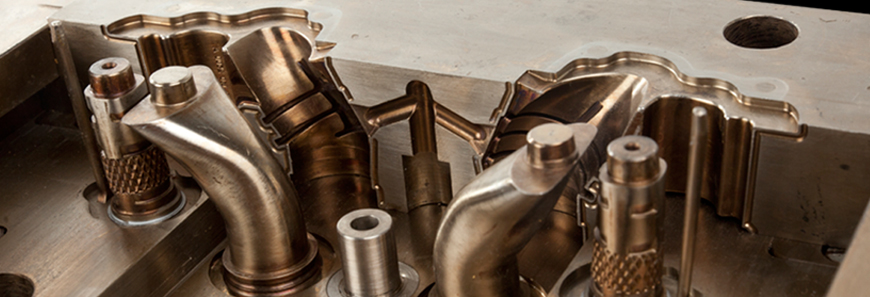

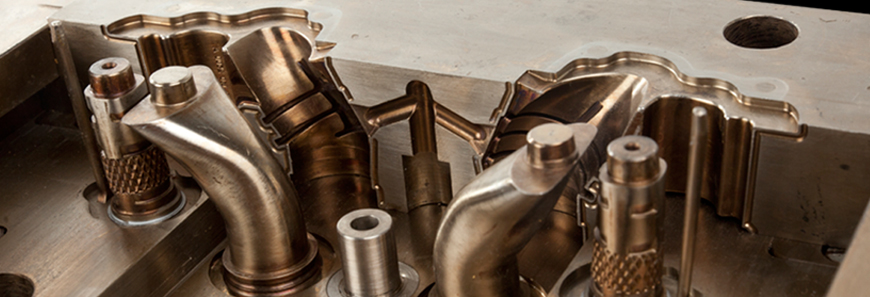

Dies And Moulds

Beryllium copper plate and rod wrought products are utilized in the plastics processing industry for plastic injection moulds, blow moulds, cavity inserts, and associated production components such as manifolds and nozzles. Also, in moulds of metal die casting dies. The material is specified in these applications due to its combination of high strength and hardness coupled with excellent thermal conductivity (as compared to tool steel and aluminium).

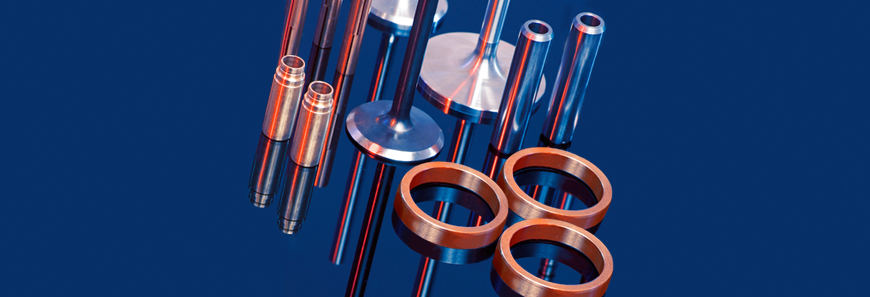

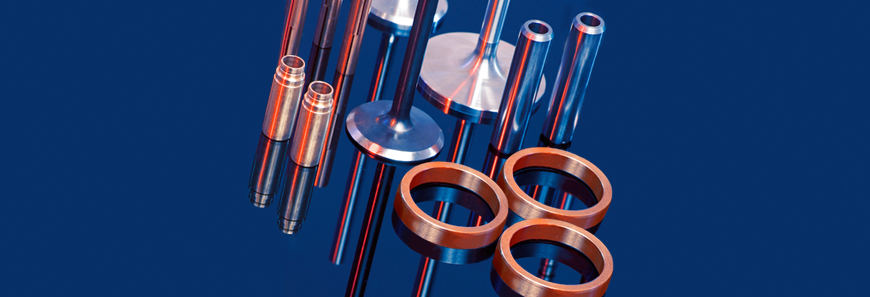

Valve Seats

In a four-stroke race engine, the valve seats play an important part in the mechanical reliability and heat management of the valves. In general, the valve seat will conduct much of the heat away from the valve head during the time the valve is shut. If we leave mechanical and dimensional considerations aside, a valve seat material with greater thermal conductivity will transfer heat from the valve to the cylinder head, and then to the cooling water circuit, more efficiently than one of lower thermal conductivity.

Special Applications

Copper Beryllium is used in a variety of applications as they provide a combination of good strength and conductivity. However, Beryllium being a strategic material and available in few countries, the cost of Copper Beryllium has significantly gone up over the years. Furthermore Beryllium and its alloys have significant hazards to health. With QTi alloys all the potential application of CuBe can be replaced with QTi alloys with certain trials and application specific requirement.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.